We do traction motors!!! The Shop Management Suite now includes repair of traction motors. Give us a call or email us

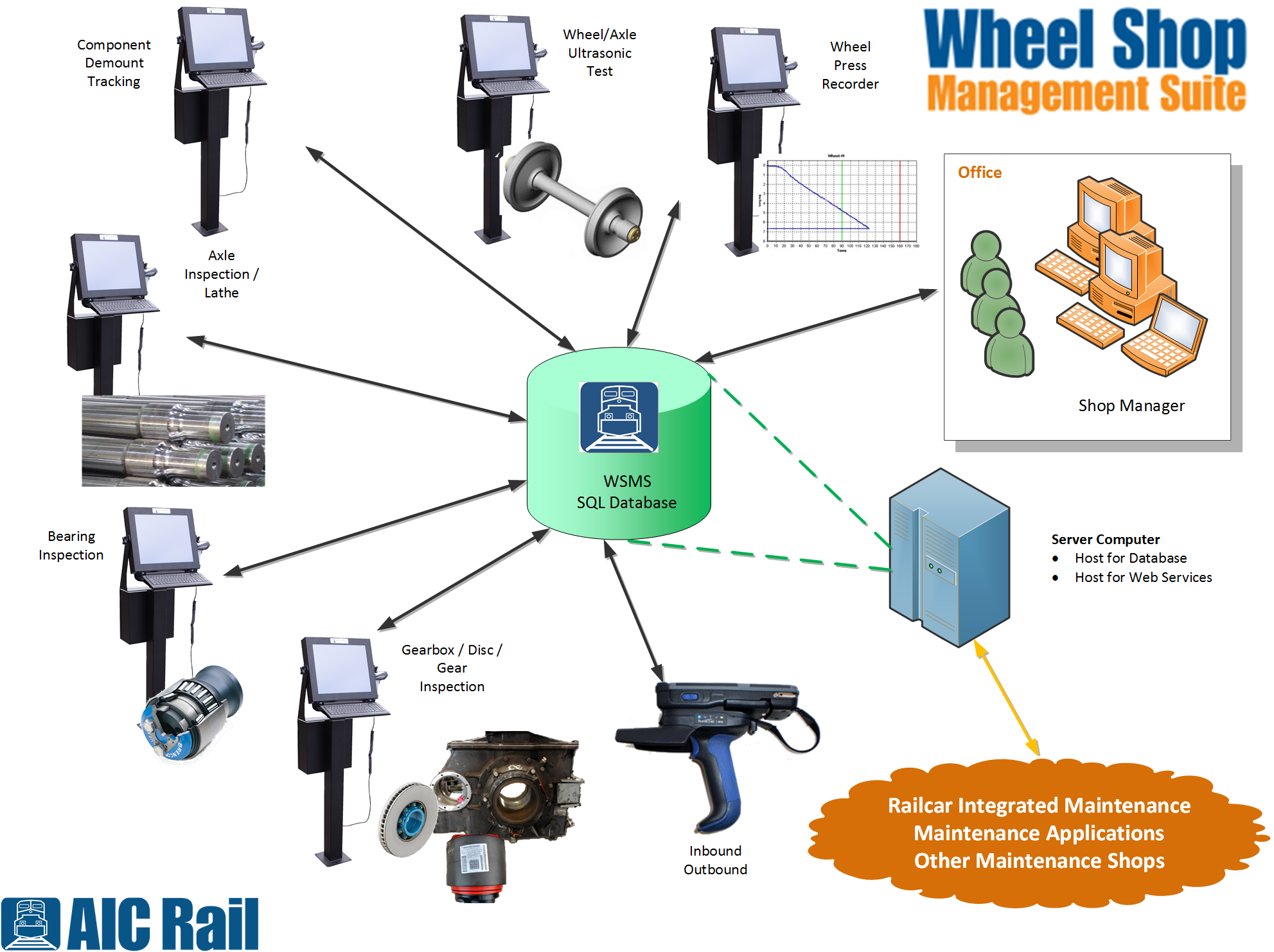

Our Shop Management Suite provides visibility into your shop operations. The WSMS allows you to track components and assemblies from the time they are received until they are shipped.

WSMS provides reporting, QA and Regulation enforcement, and data collection at all critical operations in your shop.

To print out brochures and information on current Wheelshop Automation products and services, visit our Literature Section.

Our latest products

Shop Metrix

Move your data to ths shop floor. Make real time data available to your employees to help with productivity by displaying customizable interfaces on any standard TV screen size.

Bearing Press Recorder

Record and store mounting charts for bearings pressed on by single or double ended bearing presses used in most shops.

Also collects all Component Tracking Data for AAR Reporting.

Document Viewer

Make your documentation available throughout the shop floor.

Fully configurable documents for each of your stations that can easily be shared and exported between multiple stations.

Machine Inspections

Document maintenance, setup and AAR requirements to machines in your shop. Make sure the data collected adheres to the AAR, customer, ISO and QA rules.

Our Core Products

Shop Manager

Shop Manager is the productivity powerhouse of the Shop Management Suite. See everything going on in your shop from your desk.

Wheel Press Recorder

The Wheel Press Recorder (WPR) collects wheelset data and records mounting charts for freight wheelsets. Check to see if this product is right for your shop on our Product Comparison Page.

Universal Press Recorder

The Universal Press Recorder (UPR) collects wheelset data and records mounting charts for locomotive and passenger wheelset. Check to see if this product is right for your shop on our Product Comparison Page.

Component Inspection

Component Inspection is the Swiss army knife of inspection stations. It is fully customizable for screen layout and what data to collect. Some uses are:

• Motor Frame Inspection

• Armature Inspection

• Axle Inspection

• Bearing Inspection

• Gearbox Inspection

Print Shop

Print component labels. AAR S-920 or custom labels

Outbound Tracking System

Track a wheelset as it leaves your facility, giving you traceability and accountability.

Inbound Tracking System

Track second hand wheelsets, Traction Motors and loose components as they arrive at your facility.

Bearing Tracking System

Our Bearing Tracking System and Press Recorder provides a fast and efficient method for collecting Component Tracking required information and bearing mounting charts.

Dismount Station

Misfit Tracking System

The Dismount Station Records components removed from second hand wheelsets. This allows tracking of scrap and usage by customer, wheel type, etc.

In addition it records demounted misfit wheels according to AAR Rule 1.4.1 traceability requirements.

Turn Tracking System (Reprofiled Wheels)

The Turned Tread Tracking System makes it easy to record Component Tracking required information for reprofiled wheels as well as customer specified data.

Wheel Shop Diagram

Sample Transit Shop

Traction Motor Shop Diagram